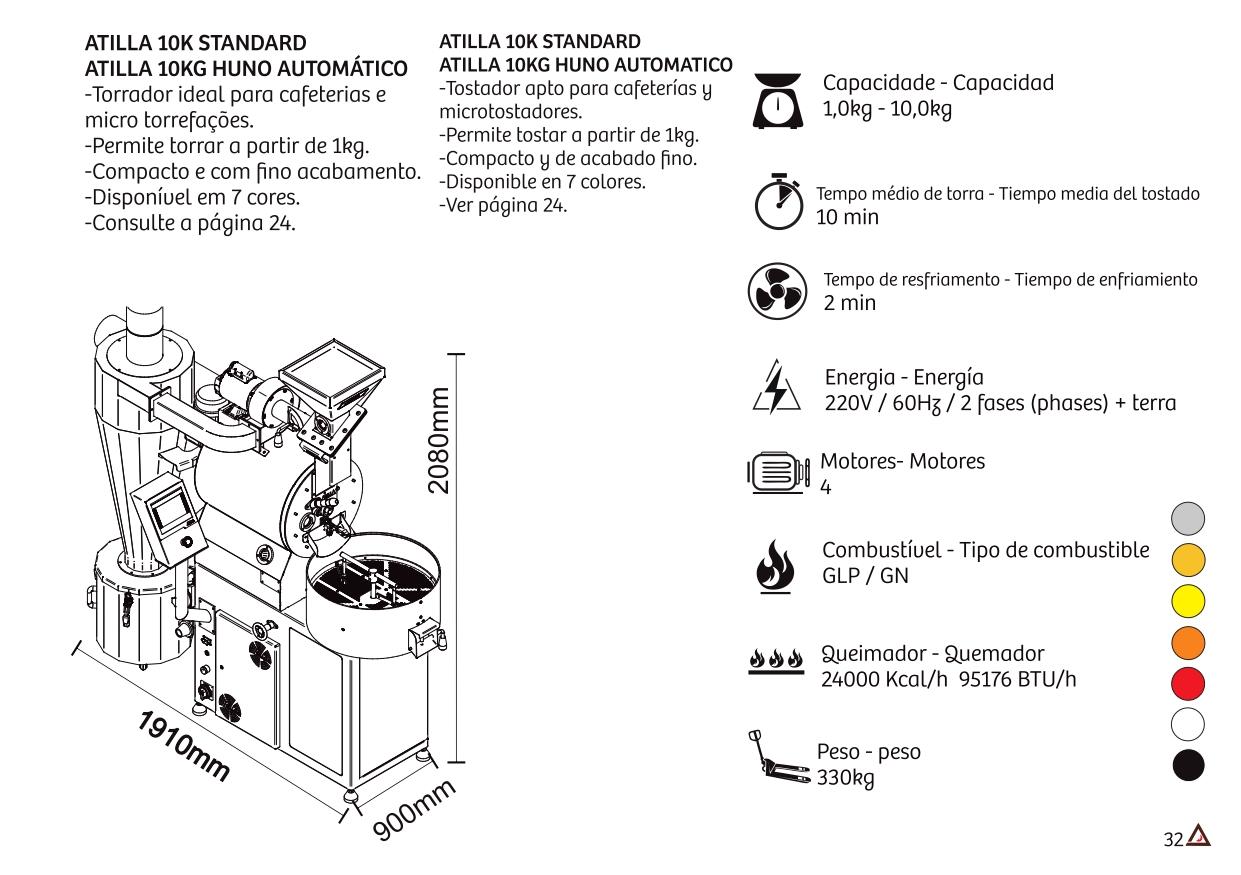

Easy operation equipment that allows temperature control during the roasting process, through the thermometer and manual adjustment of the flame height. It has an exhaust system for complete removal of smoke and films, from the inside of the cylinder to the outside, leaving the environment fresh and clean at the time of roasting. The color of the grains can be viewed through the sample collector, this at any time during the roasting process. The cooling process is carried out by suction of heat through a turbine and moving the rotating pallets. The finishing of the equipment is of a high standard and quality, including chemical treatment of steel, which ensures better adhesion of the paint, which will prevent future oxidation. The standard panel provides greater comfort and will protect the motors from overloads.